In the near future, agricultural residues such as corn stover (the stalks, leaves, and husks of the plant) and wheat straw will also be used. Long-term plans include growing and using dedicated energy crops, such as fast-growing trees and grasses, and algae. These feedstocks can grow sustainably on land that will not support intensive food crops.

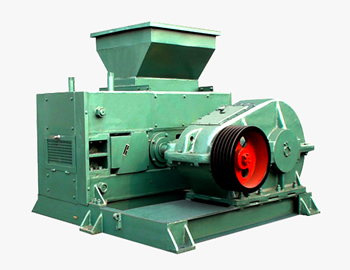

How to choose the suitable charcoal briquetting machines according to their need? We remmond that the best feasible one depends on the final usage of the charcoal briquettes, that means the end-users' potential market requirements. If customers tell us what they want to use, Fote team will design and make the proposal for customers to choose. The heating collars are made of ceramics materials, which is better than the common ones (The common ones are made of silica sand). It ensures the high heating efficiency supplying through the production. All type of Agro-Forestry waste can be used, including: wood chips, maize stalks, soybean stalks, broomcorn stalks, cotton stalks, rape stalks, peanut plants, sunflower stalks, bamboo saw dust, bagasse agro-forestry wastes, such as sawdust, wood chips, branches, crop stalks, sugarcane residue, coffee husk, paddy straw, sunflower stalk, cotton stalks, bamboo dust, palm husk, soybeans husk, tea waste, etc. Our biomass briquette machine have automatic temperature control system, charcoal briquette press machine is designed to produce high density wood or biomass briquette as biofuel. The case for promoting a widespread use of briquettes is a strong one: the current use of charcoal and firewood is contributing to wide-scale deforestation in many developing countries. The cost of charcoal is also increasing.

The recent successes in briquetting machine technology and the growing number of entrepreneurs in the briquetting sector, are evidence that biomass briquetting will emerge as a promising option for the new entrepreneurs and other users of biomass.