Today, the energy and environmental technology field constitutes the main business of KGW with an annual output of about 200 towers, however, products for the shipbuilding industry are still part of the production program as job orders on the basis of customer specifications.

Equipment options:

- Vertical ladders made of aluminum or hot-dip galvanized steel with ladder equipment (back towards tower wall or to center of tower).

- Safety system with fall protection rope or rail.

- Platforms either made of hot-dip galvanized aluminium tread plate or plywood slabs with slotted/film surface.

- Cable routing to customer's specification.

- Completely installed interior lighting.

- Entrance door with ventilation grid and insect protection as well as panic lock.

- Assembly hatch with securing cage.

- Entry staircase with hand rail.

- Double tower wall to reduce vibrations.

- HV connection element in ready-for-installation packing.

- Additional facilities, such as lift winches, etc.

General mechanical engineering Department

In response to customer requests, the area of specialized mechanical engineering and industrial projects, or pre-fabrication in these fields, has developed into a full-service area in recent years. KGW now offers one-stop shopping for all kinds of production projects, including CAD-based design, development of technical details ordered by customers (R&D), as well as complete production and installation. That makes a considerable contribution to a worldwide reputation for quality.

Perfection in mechanical engineering and industrial projects

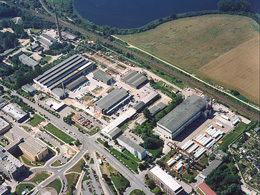

Our machine tool equipment as well as the dimensions of our production facilities and hall capacities enable us to handle any task as commissioned production.

Parts and assemblies up to 33 meters in length, 11 meters high, and up to 6 meters wide, with a total weight of 65 tons are part of our standard production range. In our large paint shop with shadow-free illumination, the components are painted using pneumatic spraying equipment or high-pressure spraying procedures. Get yourself an overview of the most important processing capabilities of our equipment park.

Quality assurance

The quality management system of our company ensures constant control of all processes and procedures according to DIN ISO 9001:2000 and has been certified on the basis of this standard since 1993.

Moreover, we meet the requirements of all classification societies, such as TÜV, GL LRS, DNV, etc., and are experienced in system approvals both in the field of maritime machinery and tower production.

KGW has always had outstanding welding potentials. The production of towers for wind power plants, deck machinery or special equipment requires special capabilities. The certificate "Großer Eignungsnachweis" according to DIN 18800 / DIN 15018 gives proof of the high qualification level of our weldors to perform welding of steel structures.

KGW Schweriner Maschinen- und Anlagenbau GmbH

Wismarsche Str. 380

D-19055 Schwerin

Germany

info@kgw-schwerin.de

www.kgw-schwerin.de

Downloads